- Knowledge Base

- Blog

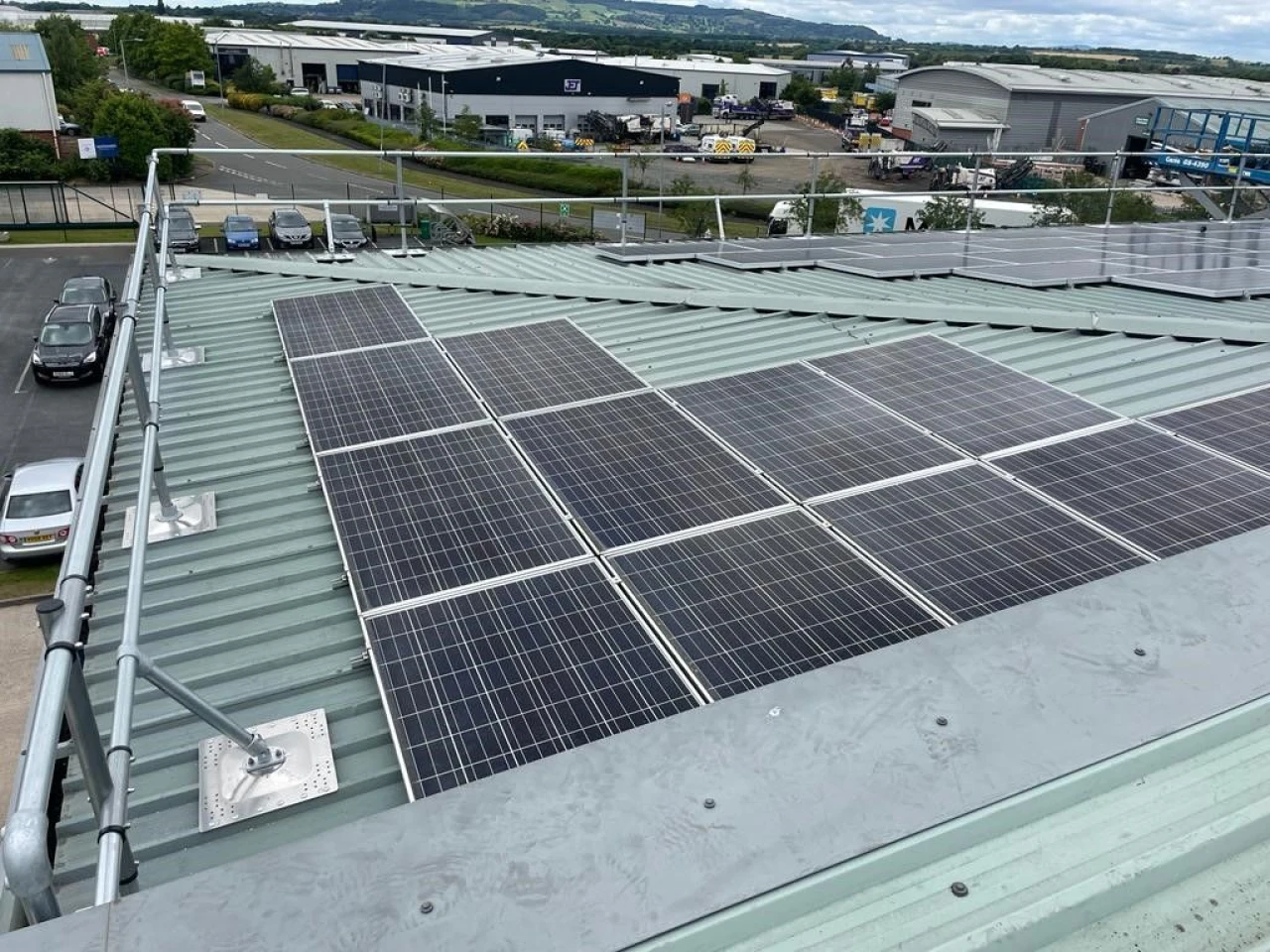

- Should you worry about our perimeter protection after guardrail installation?

Should you worry about our perimeter protection after guardrail installation?

The answer is ‘Yes you do’, as guardrail requires a programme of 12-monthly inspections to protect the worker in the event of a fall and keep workers away from a fall hazard.

Like all fall protection systems, guardrail is not a ‘fit and forget’ system. It must be properly inspected to ensure it is fit for purpose and compliant with all relevant guidance. Anyone with a building with a guardrail as a fall protection method on the roof will find there is a requirement to have this inspected under The Provision and Use of Work Equipment Regulations 1998 (PUWER 98) on an annual basis. This includes fixed and freestanding – permanent or temporary structures.

Fixed guardrail

As the name suggests, a fixed guardrail is any guardrail that is permanently attached to the structure of the building. The performance of the guardrail relies on the quality of the product, the installation and the structural integrity of the building. During an inspection, our engineers will consider not only the guardrail but also the background to which it is fixed.

When carrying out an inspection, our first job is to check all critical dimensions, to ensure the minimum height above the finished roof level is accurate, that the maximum spacing between the mid-rail and top rail is compliant and the same with the spacing between mid-rail and roof parapet. We also check the spacing of the uprights, which varies with every manufacturer, but each is assessed against that manufacturer’s instructions. Failure to achieve the minimum or be within the maximum requirements will result in our non-certification of the system, with our engineers informing the customer that remedial work needs to be carried out.

Our engineers check essential features of the building, to ensure the stability of the wall end piece, also ensuring that no fall hazard is present in the event of failure. We check the stability of the parapet via a visual and physical check and also the stability of the junction part and the corner section. Following this, we carry out a physical check of all grub screws, a function check of any additional components – such as self-closing gates and also tag the systems adjacent to the access point. Where necessary, we photograph to record our findings or via a dimensional sketch.

Freestanding guardrail

The freestanding guardrail is also subject to regular inspection. This relies on its weight and design to create a barrier and prevent a fall. Again, the performance of the guardrail relies on the quality of the product, its installation and the nature of the background where it’s located. As with fixed guardrails, we would check and inspect the critical dimensions, the spacing of the uprights, the stability of components, the junction part and the corner unit. Any observations would be recorded visually or in writing and recommendations for remedial action given to the customer by our engineers.

It is often the case that building owners overlook the fact that fall protection systems, such as guardrails, require regular inspection. This can be a costly mistake in the event of an accident. Regular inspection of guardrails, whether fixed or free-standing, is essential to ensure a building is fully compliant and that contractors and maintenance staff are offered the best possible protection.

Learn more about...